Protection for your antenna – 4a better connection

High-performance radome solutions

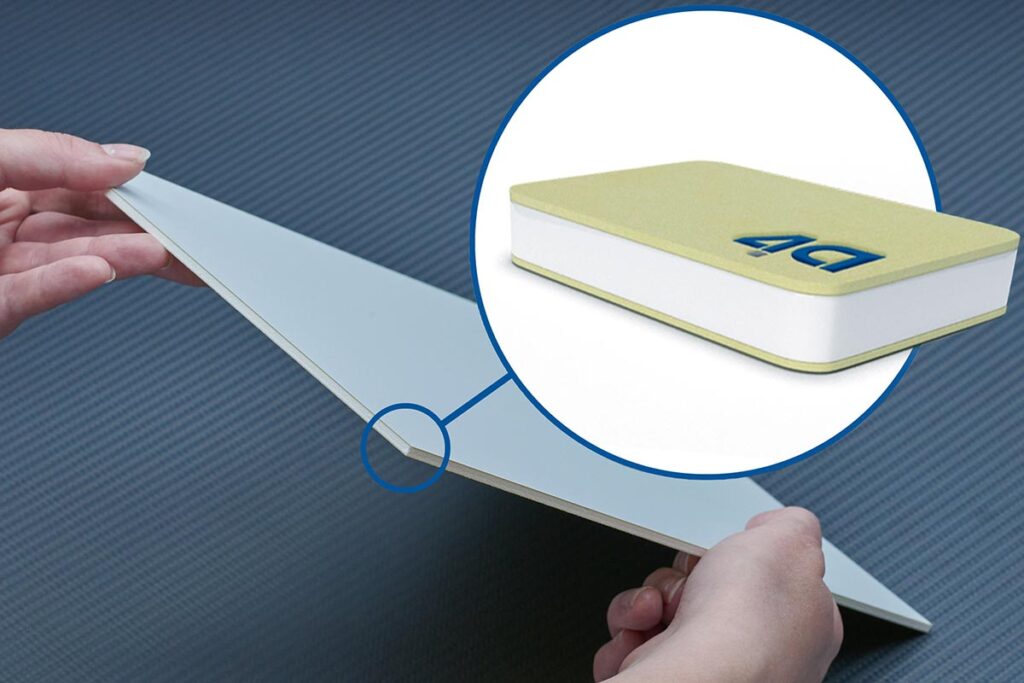

4a manufacturing is specialized in design and production of sandwich radomes starting from sub 10 GHz up to millimeter wave range. In our unique portfolio we offer standard radome and housing solutions as well as customer specific radomes that are designed for application specific requirements.

-

Radomes adaptable to many applications

-

Wide Frequency Range: sub 10 GHz up to 300 GHz

-

Optimum balance between RF transparency and mechanical stability

-

Customer-Centric Approach and Efficient Manufacturing

-

Flexible regarding materials and thicknesses to achieve the required electromagnetic behavior

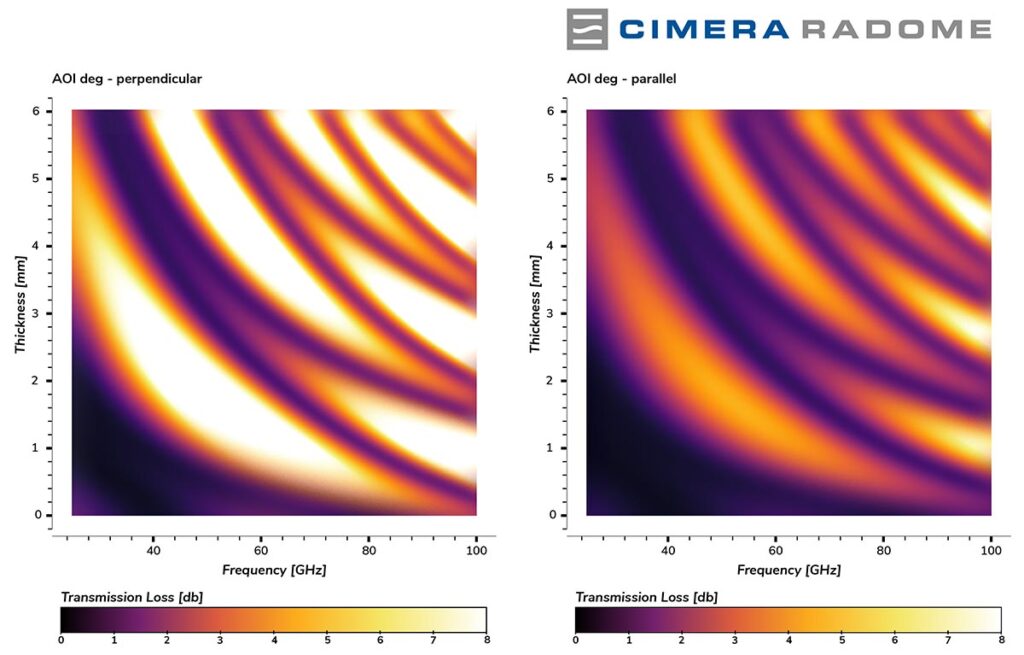

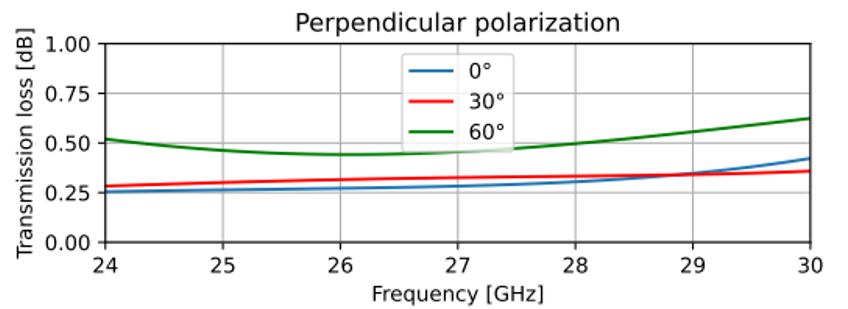

CIMERA® radomes are designed and continuously optimized with an in-house developed software tool that ensures our products to meet our customers’ requirements. Our team of researchers, who are constantly developing new ways to improve our products and services, works closely with our customers to determine together their specific requirements to create a customer-specific solution.

Our deep understanding of sandwich-structured composite materials along with an appropriate stack-up design process set us apart from our competitors. We use radome materials that are specifically selected to provide excellent electromagnetic performance while also having high mechanical durability and strength. Our radomes are designed to have low insertion loss and high transmission efficiency in the frequency range of sub 10 GHz up to 300 GHz, including 5G mmWave radio systems (small cells), satcom terminals, automotive radar systems. Taking automotive applications as an example, we understand the challenge of environmental impacts like stone chips or hail and for such we have developed a specific radome type to meet these requirements.

Our manufacturing processes are versatile, and we are highly flexible, ideally suited for developing a proprietary technology for manufacturing innovative sandwich radomes. We use a combination of automated and manual processes to ensure that each radome is manufactured to the highest quality standards, which are regularly audited and ISO certified. Our advanced processes allow us to produce high-end radomes quickly and efficiently, which means we can deliver in a timely manner.

At 4a manufacturing, we are committed to providing our customers with the best possible products and service. We have a customer-centric approach and therefore, work closely with our customers throughout the entire design, development, and manufacturing process.

We are a world leading competence partner and provider of lightweight, high frequency sandwich radomes for mmWave and broad frequency range applications, including, for example, automotive radar systems and satcom applications. Our customer-specific engineering process and material know-how along with multilayer stack-up design ensure that our radomes meet the highest quality standards and provide excellent electromagnetic performance. Our proprietary manufacturing processes allow us to deliver our products quickly and efficiently, where we ensures that our customers are satisfied with their purchase.

CIMERA® Advantages

As a leading radome solutions provider, 4a manufacturing understands the importance of a complete and efficient workflow in radome engineering and production. Our solution ensures high-quality and efficiency from concept to the finished product. This complete workflow helps to achieve your tailored radome solution to your antenna.

-

Radomes for Versatile Industry Applications

-

Individual Geometries & Mounting Solutions

-

Validated Simulation for Radomes

-

Rapid Prototyping for Flat Samples

-

End to End Quality Assurance

-

Manufacturing Partner – from Prototype to Serial Production

Radomes are essential components in many industries, including aerospace, security, and telecommunications. They protect sensitive equipment from environmental influences while allowing signals to pass through. Radomes are designed to meet stringent requirements, including environmental resistance, high-frequency transparency, and lightweight design. To ensure the final product meets all requirements, a thorough workflow is necessary. This process involves multiple phases, such as design and simulation, prototyping, testing, and manufacturing. Each stage must be carefully planned and execution to meet the exacting demands of our customers.

Unique Provider Who Gives Simulation Data of the Specified Radome

We are a unique radome provider, using plane wave approach, simulation data and expertise in the radome design process. This data guides us in creating effective and tailored radomes with our customers for their antennas. The simulation is the first step in an engineering project towards prototypes and production.

Fast Sample Production for Early Testing

CIMERA® radome solution offers a crucial advantage: rapid sample production for early testing. We understand the pivotal role of the initial phases in radome production, and thus, we provide fast sample production to enable prompt testing and evaluation of the radome design. Our team of experts can assist in optimizing your design for manufacturing and rapidly deliver a prototype. This allows you to test and adjust the radome sample before proceeding to the next production phase.

Experience in Providing Suitable Radomes for Different Markets

The 4a manufacturing possess extensive experience in providing suitable radomes for diverse markets, each with its unique requirements. We collaborate with clients in various industries like satcom, automotive, security, and telecommunications, offering expertise in material selection, manufacturing processes, and testing to ensure your radome aligns precisely with your market’s requirements.

Radio Frequency Transparent

CIMERA® radome offers two versatile options: RF (radio frequency) transparent windows and complete housing solutions with integrated radomes. Our RF transparent windows enable signal passage while safeguarding sensitive equipment from environmental elements. On the other hand, our integrated radome housing solutions are comprehensive solutions for your antenna needs. We specialize in designing and manufacturing customized housing solutions tailored to your specific application requirements.

Completely Tested and Characterized Radomes

With CIMERA® radomes, we provide fully tested and characterized solutions. Our advanced testing processes and equipment guarantee that each radome meets all required specifications.

Benefits of Using CIMERA® Complete Radome Solution

Our CIMERA® radomes guarantee quality and efficiency throughout the entire process, from concept to the final product. With fast sample production, agile project management, and a proven track record across diverse markets, we help customers obtain the ideal radome for their antenna. Offering radio frequency transparent windows or complete housing, along with tested and characterized radomes and simulation data, sets us apart as an industry leader.

If you’re looking for a complete radome solution, get in touch with our technical sales team to learn more about how we can help you achieve your radome production goals.